Microsieve product development is one of the design and engineering services offered by Aquamarijn. This is often used for proof-of-concept or feasibility studies as well as visual and form prototyping (modelling). Aquamarijn makes functional prototypes out of concepts to simulate manufacturability and to test the user experience with the prototype or model.

Aquamarijn has a large prototyping output in microsieve based devices. Short lead times are essential to help customers test their concepts and ideas in practice. Microsieve based prototypes can actually demonstrate feasibility of research ideas to different levels in the organization. Thus, the microsieve based prototype or model forms the basis for making adequate project and investment decisions.

Aquamarijn’s design department is well trained and experienced in realizing your prototypes. A combination of 2D and 3D CAD and CAM, calculations, modelling software, micro and nanoengineering, surface chemistry know-how and experience enables us to optimize and realize fast prototypes.

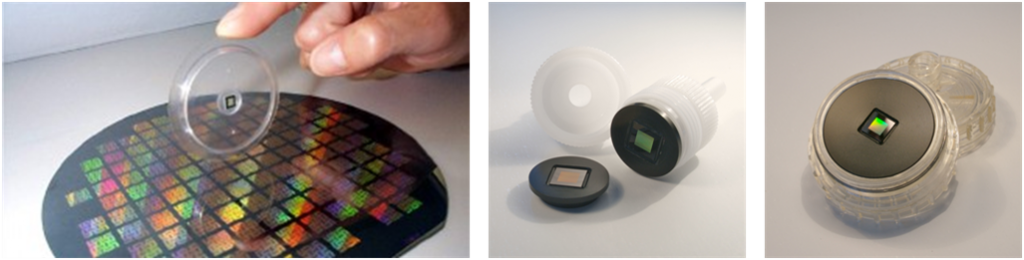

Product development based on microsieve chips

Aquamarijn uses manufacturing processes for microsieve prototyping chips to ensure quality and upscaling compatibility. Aquamarijn has access to cleanroom facilities to manufacture and characterize the microsieves.

For other devices, interfacing and packaging we use new technologies like 3D printing and additive manufacturing. In addition, we have extended network of partners for rapid prototyping using other fabrication methods.