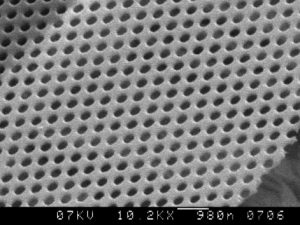

At Aquamarijn we design, prototype and manufacture membrane based MEMS products such as microsieves, nanostencil shadow masks, biomedical filters or TEM-grids. We introduced a revolutionary micro filtration membrane: microsieves, micro-engineered membranes produced using silicon micromachining. The most important features of the microsieve membrane technology are the precision-etched pores (depending on your application, 0.1-50 µm) and a thin membrane (with a thickness of 0.5 to 2 µm) with a surface roughness down to a few nm. Take a look at our standard products in our web shop. If you require something else do not hesitate to contact us.

Special properties of the microsieve® are:

- Well defined pore shape

- Uniform pore size distribution (standard deviation less than 1%)

- Available with customer specific inorganic or organic coatings

- Optically flat; this allows fast microscope scanning without adjusting focus

- Smooth pores showing minimal cell rupture (f.i. hemolysis or blood platelet activation)

- Integration with Micro Total Analysis Systems (µTAS)

- Isolation of vulnerable cells when using a microsieve® which is thinner than the pore size

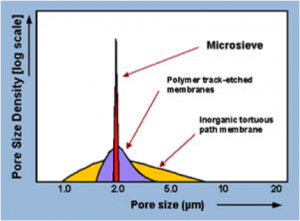

Pore Size Distribution of different membranes compared

The microsieve membrane technology offers perfectly controlled uniform perforations down to 0.1 µm. The separation behavior will strongly benefit from a narrow pore size distribution. This avoids the problem relating to non-uniform pore distributions, i.e. large particles slipping through the pores, particles that the membrane should retain. The Aquamarijn microsieve® has the narrowest pore size distribution ever possible. Moreover, the shape is not restricted to circular cross-sections for the pores, strongly elongated, square, rectangular cross-sections are also possible. Also the relative pores position on the membrane has a great freedom of design, which allows tuning of the porosity.

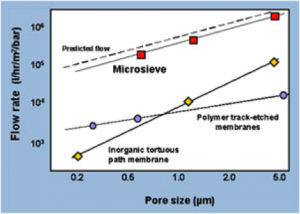

Clear Water Flux of a Microsieve

The flow rate of the Aquamarijn microsieve® is the highest yet available due to the uniform pore size, the high pore density and the small thickness of the membrane layer. The clear water flux is at least one order of magnitude larger than the best conventional filters and approaches nearly the theoretical maximum throughout the whole pore size range. In a cross-flow configuration fouling is easily prevented at relatively low cross-flow pressures due to the excellent overall flatness of the membrane layer. For anyone who would like to try the features which the microsieve membrane technology offers, we sell high flux sieve membranes in our webshop. For custom designs please contact us.

Microsieve properties

| Membrane Size | 1 to 150 mm,Circular or Rectangular |

| Membrane Thickness | 0.1 to 2 µm |

| Pore Size | 0.1 to 100 µm |

| Membrane Material | Ceramic, Si3N4 or SiO2 |

| Support | Silicon or Other |

| Support Thickness | 0 to 500 µm |

| Membrane Coating | Ceramic, metallic, monolayer or polymeric, |

| Temperature Resistance | -50 to 800°C |

| Chemical Inertness | Inert to (in-)organic solvents |

| Surface Roughness | 1 to 100nm rms |

| Protein Adsorption | antifouling coatings possible |

| Refractive Index | 1 to 2.1 |

| Optical Flatness | Yes |

| Operating Pressure | 0 to 0.5 MPa |

| Cleaning | Cross-Flow/Back Pulsing/Aggressive Solvent/Oxygen Plasma |

| Sterilisation | Yes |

| Clear Water Flux | See Graph |