All activities in the field of drug delivery and aerosol technology based on microsieves are done at Medspray. The company Medspray is focusing on spray technology using microsieves. Aquamarijns knowledge and expertise is used for further product development and manufacturing of the chips.

All activities in the field of drug delivery and aerosol technology based on microsieves are done at Medspray. The company Medspray is focusing on spray technology using microsieves. Aquamarijns knowledge and expertise is used for further product development and manufacturing of the chips.

Medspray designs and develops aerosol and spray devices. Based on customer input and regulatory input (following the ISO 20072 standard for aerosol drug delivery devices), a design is made of the novel device. This design is verified in vitro in our aerosol lab and then validated in vivo. Risk management according to ISO 14971 is an important part of the development, as are usability and comfort studies. Products can be CE certified to speed up your clinical programs

Medspray uses established micro & nano technology processes to manufacture the spray nozzles. The orifices of our spray nozzles are tiny (1 to 30 micrometer, for reference: a human hair is 70 microns thick). Spray nozzles are created batch-wise, with several thousand nozzles from a single silicon wafer.

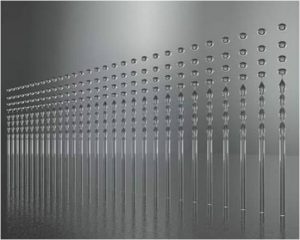

Rayleigh sprays

Our spray nozzle units are based on plain orifice nozzles, creating Rayleigh jets. A 2 micron hole creates a jet, breaking up in mono-disperse 4 micron droplet trains. The diameter of the droplets is twice the size of the orifice. The hole size can be engineered to meet the specific requirements of the device. Spray nozzle chips do not have electronic functions, it is purely a mechanical structure, made with technologies generally used to make computer chips.

Pressing water through the Medspray nozzle results in a jet which will automatically break up in droplets (Rayleigh principle). This is mono-disperse, all droplets have the same size. The droplets are twice the size of the jet. By changing the hole diameter of the spray nozzle, the droplet size can be engineered for optimal performance.

Further Reading

- Munnik, P.; de Boer, A. H.; Wissink, J.; Hagedoorn, P.; Heskamp, I.; de Kruijf, W.; van Rijn, C. J. M.; Frijlink, H. W.; Zanen, P., In Vivo Performance Testing of the Novel Medspray (R) Wet Aerosol Inhaler. Journal of Aerosol Medicine and Pulmonary Drug Delivery 2009, 22, 317-321.

- de Boer, A. H.; Wissink, J.; Hagedoorn, P.; Heskamp, I.; de Kruijf, W.; Bunder, R.; Zanen, P.; Munnik, P.; van Rijn, C.; Frijlink, H. W., In vitro performance testing of the novel medspray (R) wet aerosol inhaler based on the principle of Rayleigh break-up. Pharmaceutical Research 2008, 25, 1186-1192.

- van Rijn, C. J. M., Atomisation. In Nano and Micro Engineered Membrane Technology. Elsevier: Amsterdam, 2004; pp 335-346

- Wissink, J. M.; van Rijn, C. J. M., Smart Micromachined Nozzles for Monodisperse Aerosol Generation Using Low Pressure Rayleigh Break-up. In Proceedings of Respiratory Drug Delivery VIII (2002) Tuscon , Arizona, 2002; Vol. 2.